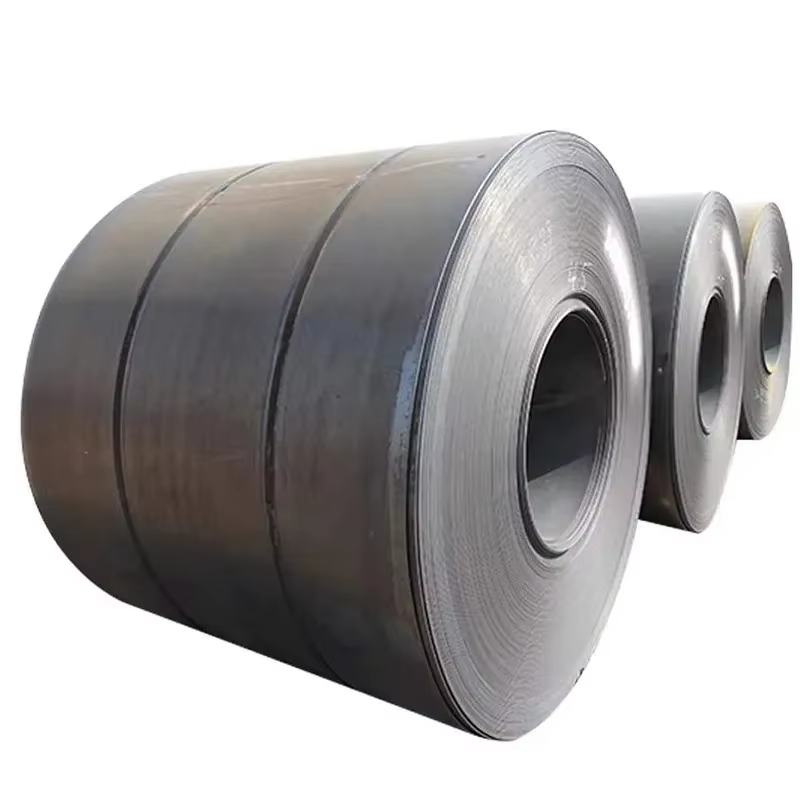

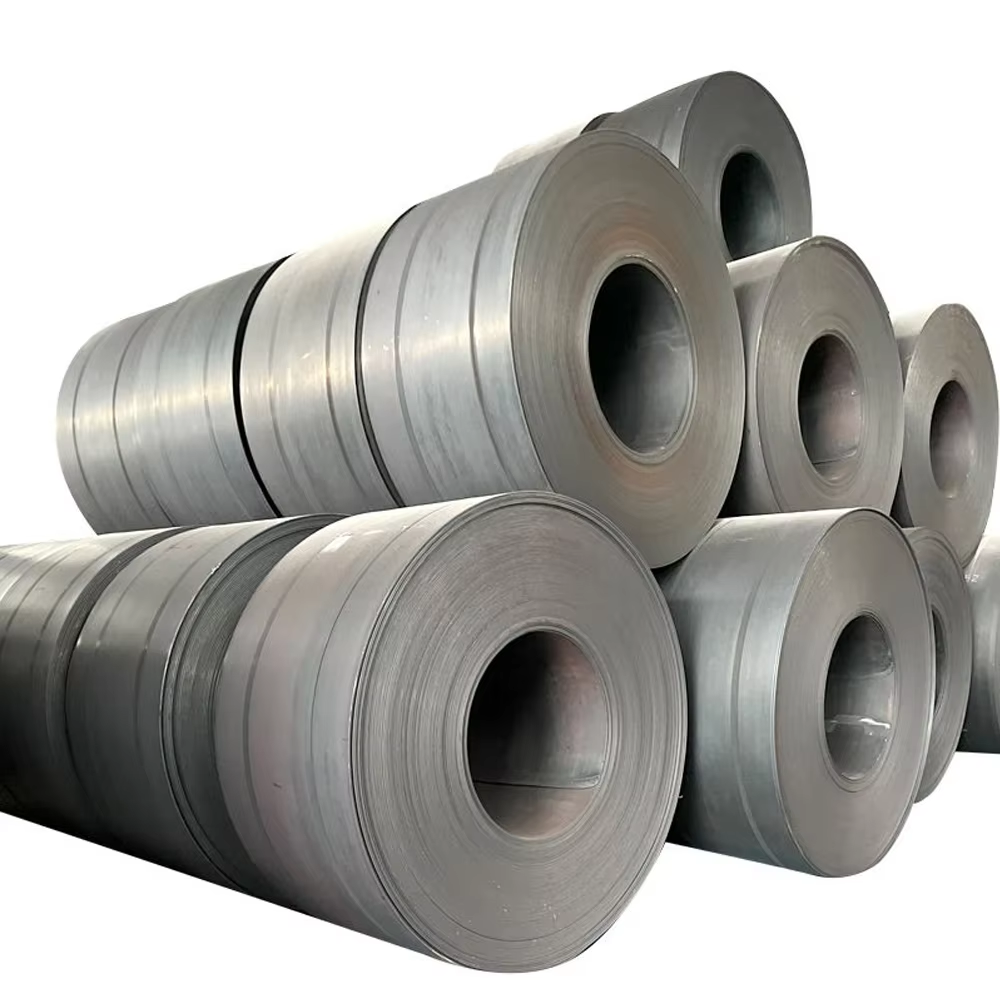

600 - 1500mm wide cold rolled coil is a versatile and widely used steel product in various industries, and Liaocheng Mingxing Pipe Manufacturing Co., Ltd. has been a leading producer of high - quality cold rolled coils in this width range since 2016. Cold rolling is a metalworking process in which steel is passed through a series of rollers at a temperature below its recrystallization temperature. This process results in a steel coil with a smooth surface finish, improved dimensional accuracy, and enhanced mechanical properties compared to hot - rolled steel. The width range of 600 - 1500mm makes these cold rolled coils suitable for a wide range of applications. In the automotive industry, they are used for the manufacture of various components, such as body panels, door skins, and roof panels. The precise dimensions and good surface finish of the cold rolled coils allow for easy stamping and forming into the desired shapes, while the improved mechanical properties provide the necessary strength and durability for the automotive parts. In the appliance industry, 600 - 1500mm wide cold rolled coils are used to make refrigerators, washing machines, ovens, and other household appliances. The smooth surface of the coils gives the appliances a high - end appearance, and the corrosion resistance of the steel, which can be further enhanced through coating processes, ensures the longevity of the products. In the construction industry, these cold rolled coils are used for roofing, wall cladding, and other architectural applications. Their lightweight nature and ease of installation make them a popular choice for building projects. They can also be coated with various materials to improve their weather resistance and aesthetic appeal. At Mingxing Pipe, we use advanced cold rolling mills to produce 600 - 1500mm wide cold rolled coils with high precision and consistency. We carefully control the rolling parameters, such as rolling force, reduction ratio, and speed, to achieve the desired thickness, width, and surface quality. Our factory is equipped with state - of - the - art quality control equipment to monitor the mechanical properties, chemical composition, and surface condition of the coils. We offer a variety of steel grades for our cold rolled coils, including carbon steel, high - strength low - alloy steel, and stainless steel. This allows our customers to select the most suitable material for their specific applications. We can also provide additional processing services, such as slitting, cutting to length, and coating, to meet the customer's exact requirements. Our sales team has extensive knowledge of the applications of 600 - 1500mm wide cold rolled coils. They can provide technical advice and support to customers, helping them select the most suitable coils for their projects. We also offer competitive pricing and flexible delivery options to meet the diverse requirements of our customers. As we continue to expand our market presence in Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, we are confident that our 600 - 1500mm wide cold rolled coils will be in high demand. We invite new and existing clients to collaborate with us, leveraging our high - quality products and professional services for successful projects in various industries.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy