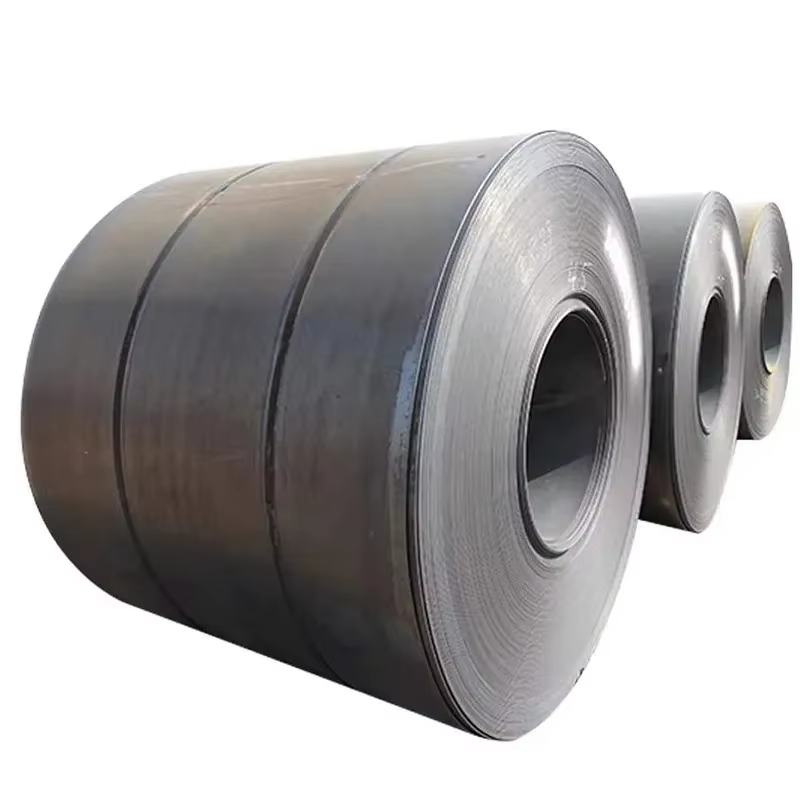

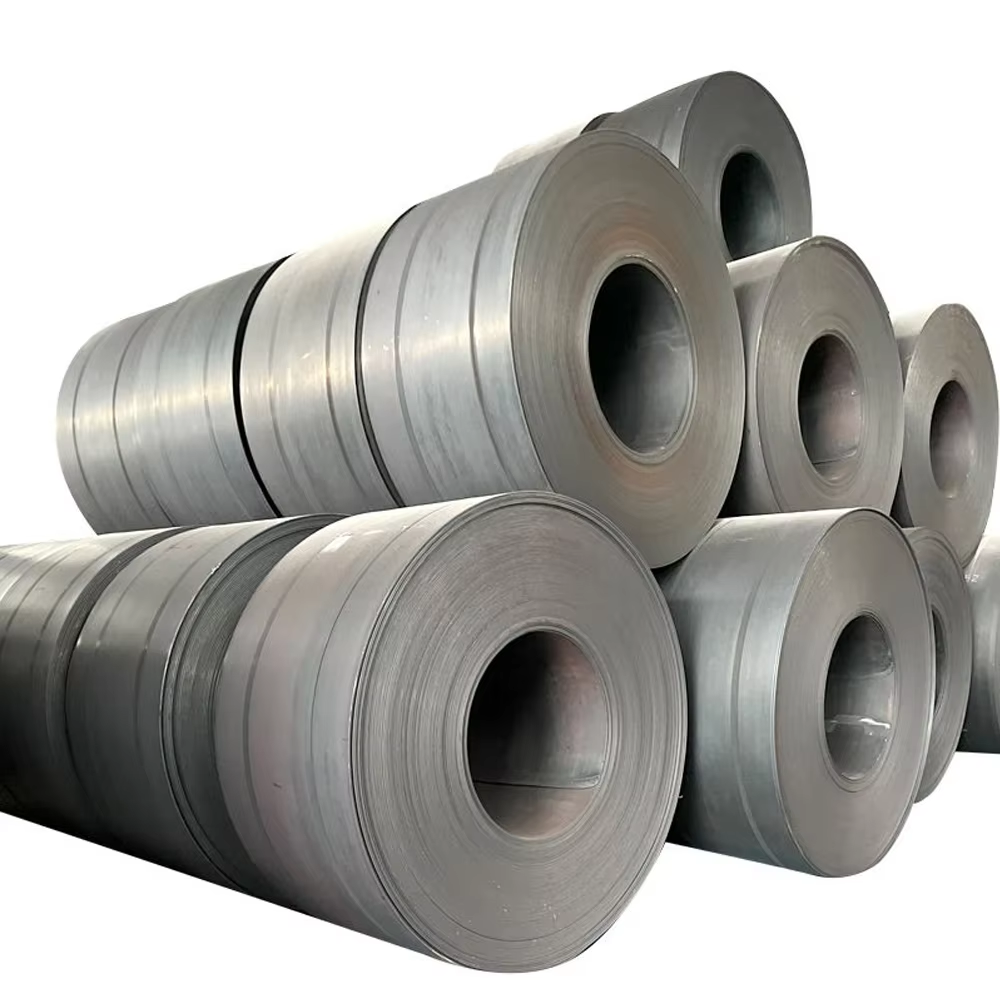

Liaocheng Mingxing Pipe Manufacturing Co., Ltd. stands as a prominent name in the global steel industry, offering a wide range of high - quality steel products, among which cold rolled coil for construction is a standout. Since our establishment in 2016, we have been committed to producing steel products that meet the highest international standards. Cold rolled coil for construction from Mingxing Pipe is manufactured using advanced production lines. The cold - rolling process gives the coil a smooth surface finish and precise thickness control, which are crucial for construction applications. In the construction field, these coils are widely used in the fabrication of structural components such as beams, columns, and frames. Their excellent formability allows them to be easily shaped into various complex profiles according to the specific design requirements of construction projects. Our cold rolled coils are made from high - grade steel raw materials, ensuring high strength and durability. This means that structures built using our products can withstand heavy loads and harsh environmental conditions over an extended period. Moreover, our strict quality control measures at every stage of production guarantee that each coil meets the specified mechanical properties, such as tensile strength and yield strength. The cost - effectiveness of our cold rolled coil for construction is another significant advantage. Through effective cost management, we are able to offer competitive prices without compromising on quality. This makes our products an attractive choice for construction companies looking to optimize their project budgets. Whether it's a large - scale infrastructure project or a residential building construction, our cold rolled coils can provide reliable and long - lasting performance. We also have a professional sales team that is well - versed in the construction industry and can provide expert advice on product selection and application. Our innovative R&D team continuously works on improving the quality and performance of our cold rolled coils to keep up with the evolving needs of the construction market. With our global reach, we have successfully supplied cold rolled coil for construction to markets in Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, building long - term partnerships with clients worldwide.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy