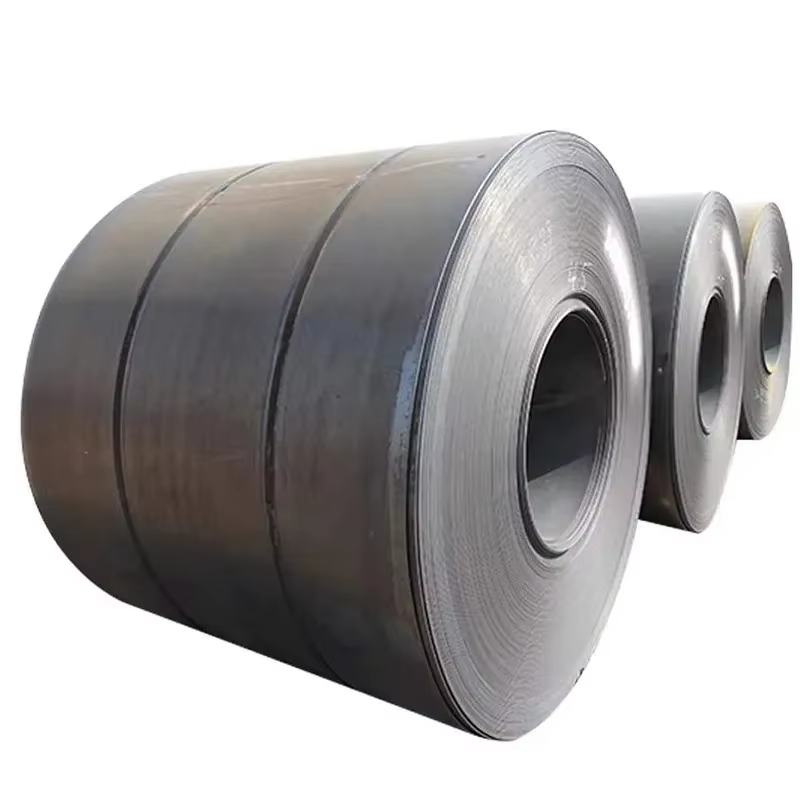

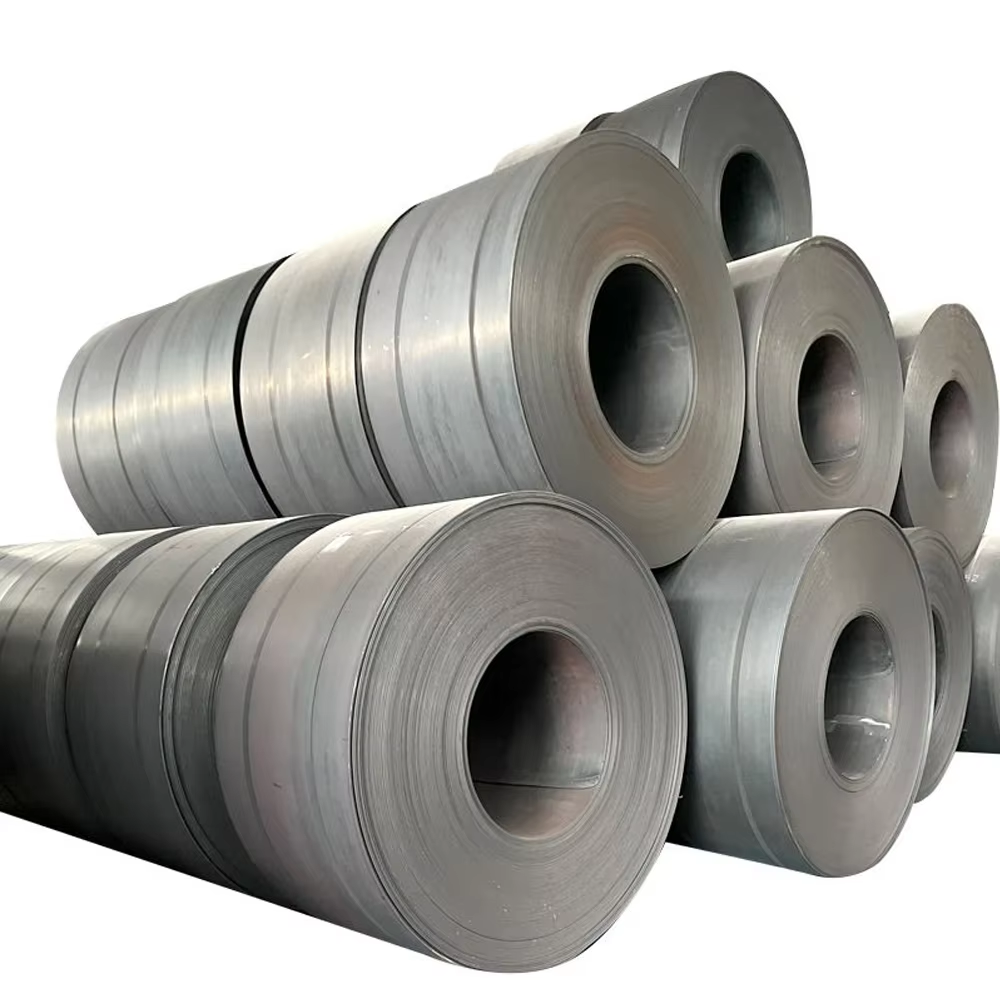

Laocheng Mingxing Pipe Industry Manufacturing Co., Ltd. produces galvanized cold rolled coils that combine the precision of cold rolling with the corrosion resistance of galvanization. These coils are made by cold rolling steel to achieve tight thickness tolerances and smooth surfaces, followed by a galvanization process (hot-dip or electro-galvanizing) to apply a protective zinc layer. The cold rolling process enhances material strength and hardness, while the zinc coating provides excellent rust protection, making them suitable for automotive body panels, electrical enclosures, and construction components. The company’s advanced production lines ensure uniform coating thickness and strong adhesion, with options for different zinc weights and surface finishes. Rigorous testing includes salt spray corrosion tests, Erichsen cupping tests, and dimensional checks to guarantee performance and quality.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy