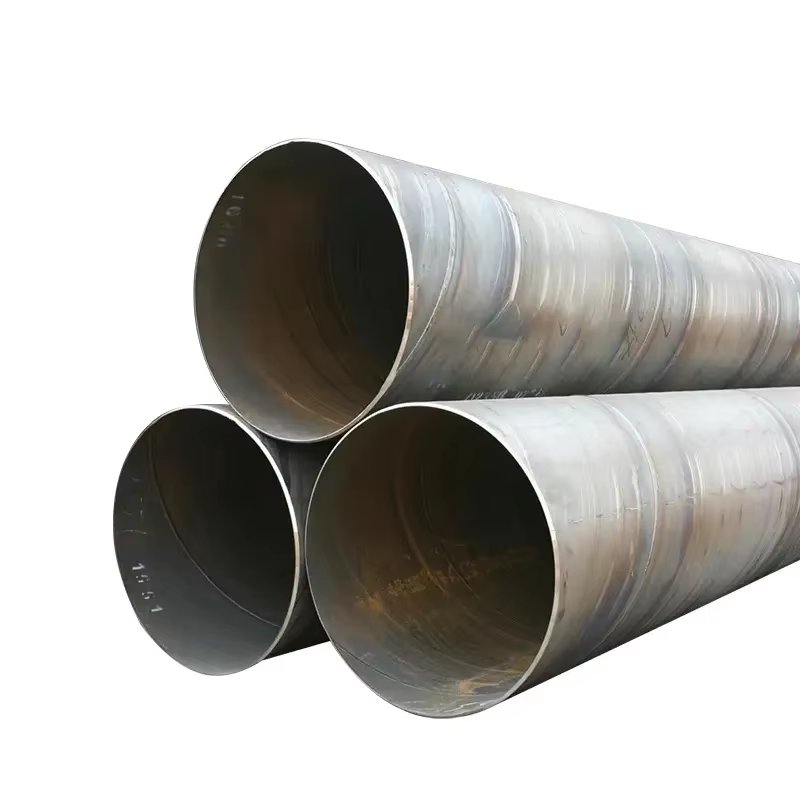

Liaocheng Mingxing Pipe Manufacturing Co., Ltd., established in 2016, has emerged as a significant force in the global steel sector. Among our diverse range of high - quality steel products, hydraulic welded steel pipes hold a prominent position. These pipes are engineered with precision to meet the demanding requirements of hydraulic systems. Our production process combines advanced technology with strict quality control measures. The raw materials used are of the highest grade, ensuring the pipes' durability and strength. Hydraulic welded steel pipes from Mingxing Pipe are designed to withstand high - pressure environments, making them ideal for applications in industries such as construction, machinery manufacturing, and automotive. The welding process is carried out with utmost care to guarantee a seamless joint, which is crucial for the efficient flow of hydraulic fluids. Our professional R&D team continuously works on improving the design and performance of these pipes to keep up with the evolving market needs. With our efficient production lines, we can produce hydraulic welded steel pipes in various sizes and specifications to cater to different customer requirements. We serve international markets, including Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, providing reliable and high - quality products. Our sales team is dedicated to understanding customer needs and offering personalized solutions. By choosing Mingxing Pipe's hydraulic welded steel pipes, customers can expect long - lasting performance, cost - effectiveness, and excellent after - sales service, all in line with our company's philosophy of integrity, innovation, dedication, and mutual benefit.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy