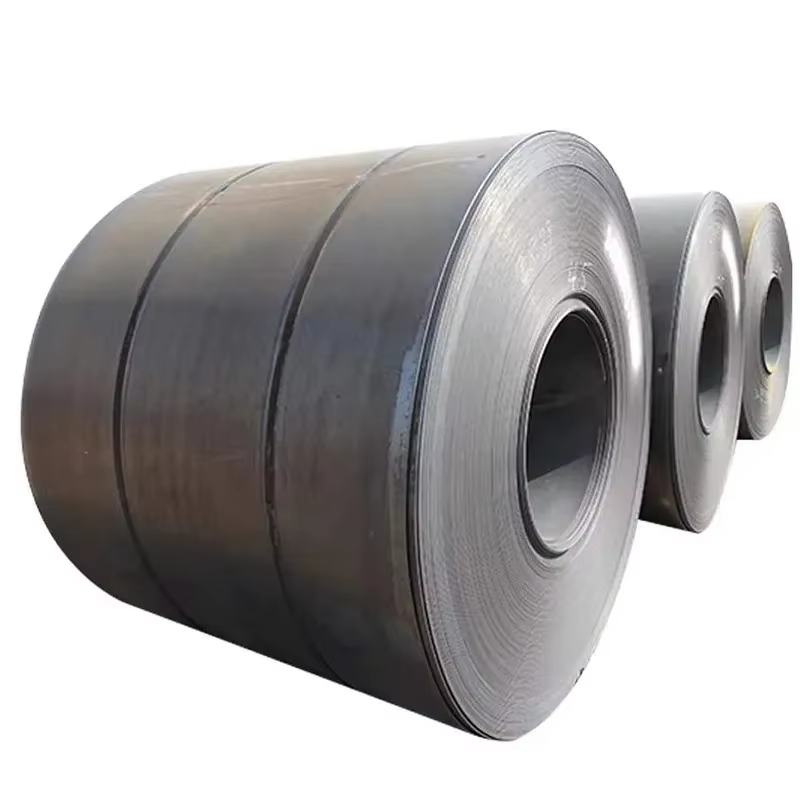

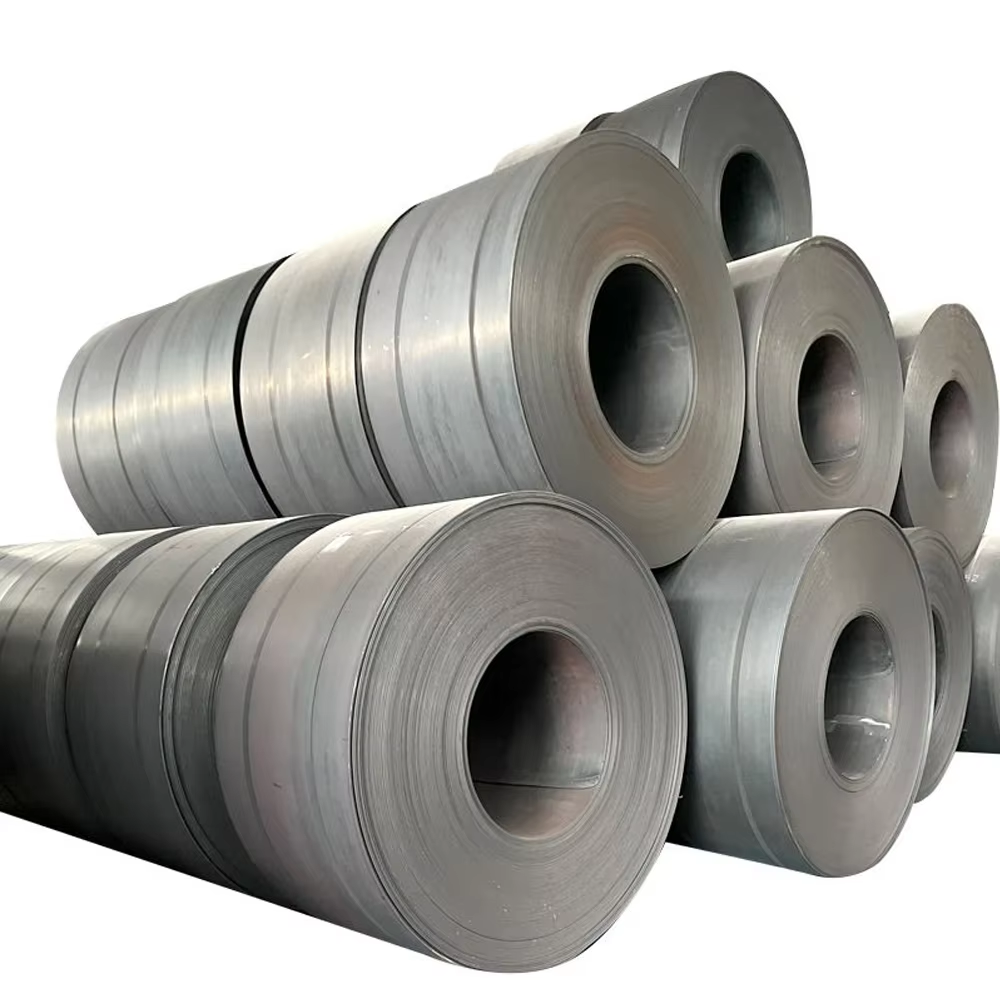

Liaocheng Mingxing Pipe Manufacturing Co., Ltd. takes pride in its production of precision cold rolled coils, a testament to our commitment to excellence and innovation. Our precision cold rolled coils are manufactured using cutting-edge technology that ensures precise control over thickness, width, and surface finish. These coils are widely used in applications that require high levels of accuracy and consistency, such as in the manufacture of automotive parts, electrical appliances, and precision instruments. Our production process is designed to minimize variations and ensure that each coil meets the stringent quality standards that our clients have come to expect. With a focus on continuous improvement and customer satisfaction, we strive to offer precision cold rolled coils that not only meet but exceed industry norms. Partner with us for a collaborative journey towards mutual growth and success.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy