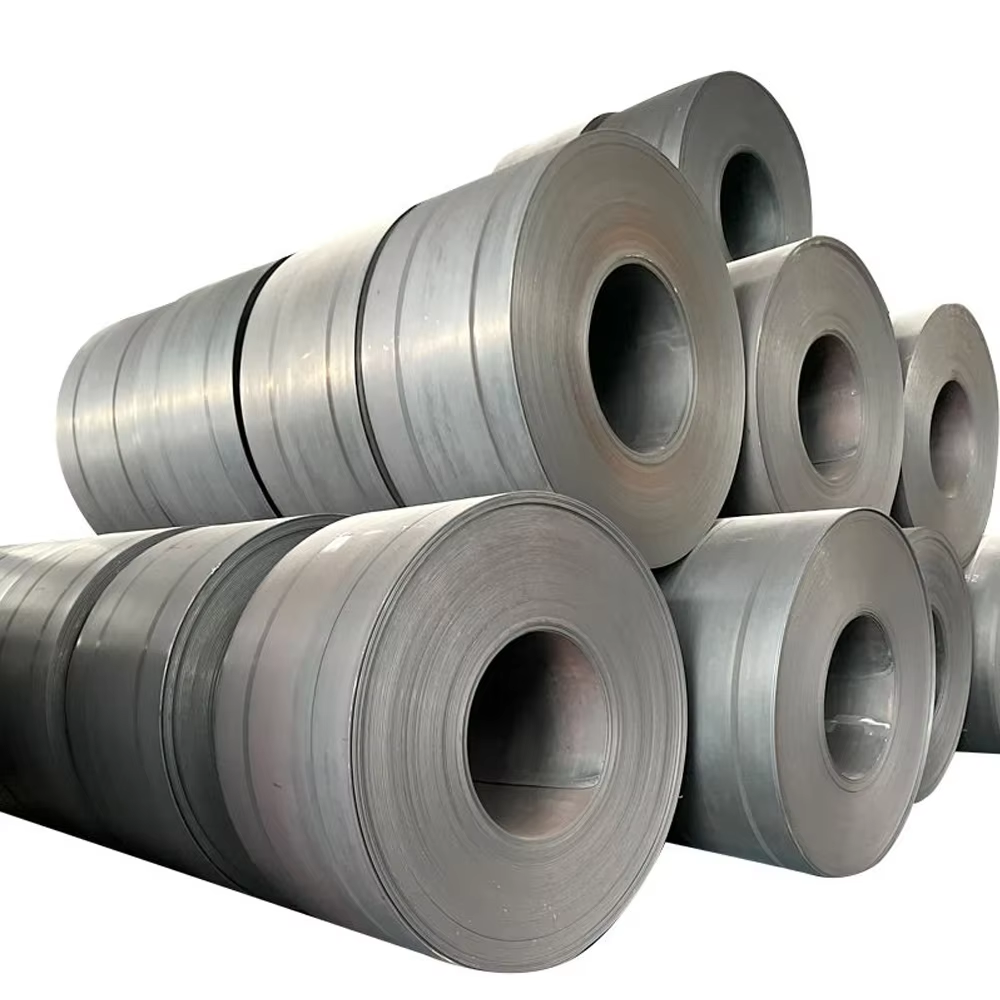

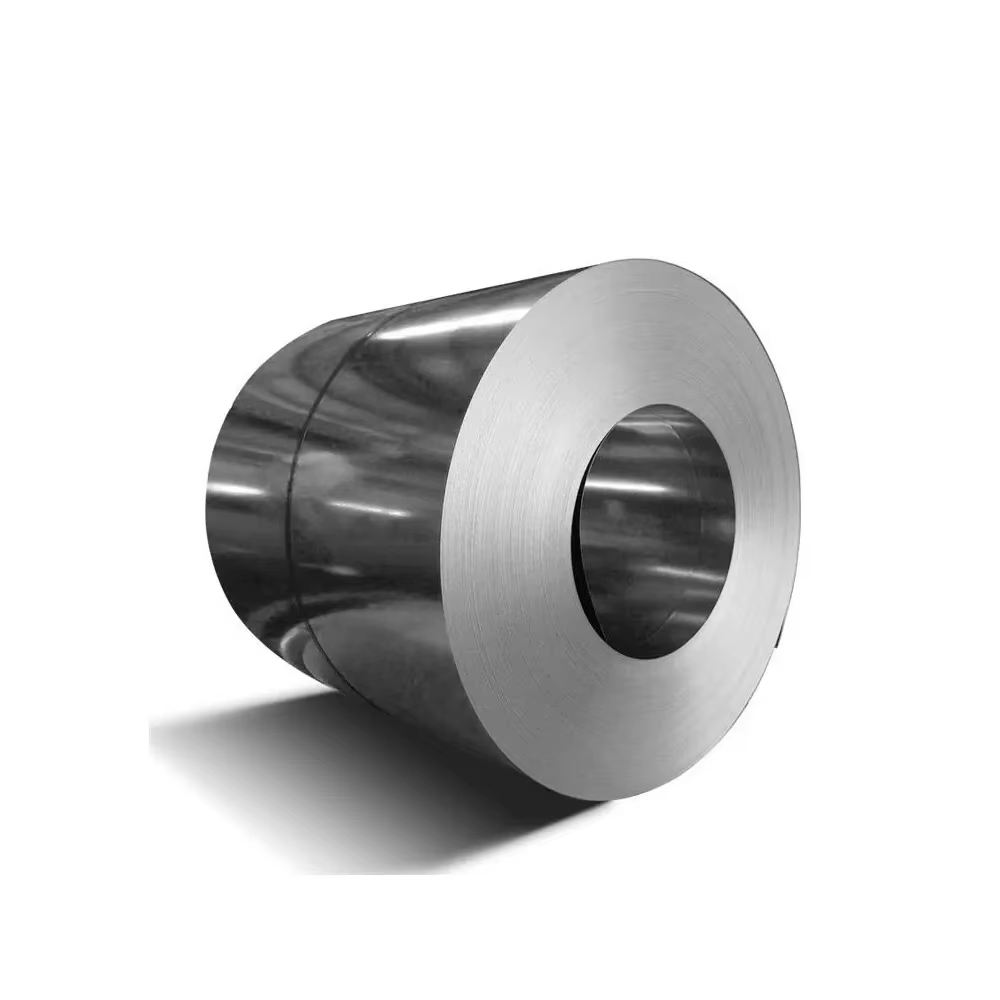

Hot rolled stainless steel coil is a fundamental product in the stainless steel industry, and Liaocheng Mingxing Pipe Manufacturing Co., Ltd. has been a leading producer of high - quality hot rolled stainless steel coils for the global market since its founding in 2016. The hot rolling process involves heating stainless steel billets to a high temperature and then passing them through a series of rollers to reduce their thickness and increase their length. This process gives the stainless steel coil a unique set of properties and characteristics. One of the main advantages of hot rolled stainless steel coil is its relatively low cost compared to cold - rolled stainless steel coil. The hot rolling process is less energy - intensive and can be carried out at a faster rate, making it a more cost - effective production method. Additionally, hot rolled stainless steel coils have a slightly rough surface finish, which can be beneficial in certain applications where a high - gloss surface is not required. At Mingxing Pipe, we use high - quality stainless steel grades as the raw material for our hot rolled coils. We offer a wide range of grades, including 304, 316, 321, and 410, among others. Each grade has its own specific chemical composition and mechanical properties, allowing our customers to choose the most suitable material for their applications. The hot rolled stainless steel coils produced by us have good formability. They can be easily bent, stamped, and welded into various shapes and structures. This makes them suitable for a wide range of applications in industries such as construction, automotive, and industrial equipment manufacturing. In the construction industry, hot rolled stainless steel coils are used for the production of structural components, such as beams, columns, and braces. Their high strength and corrosion resistance make them ideal for building frameworks, especially in areas with harsh environmental conditions. In the automotive industry, they are used for the manufacture of exhaust systems, chassis parts, and other components, where their durability and heat resistance are required. Our factory is equipped with advanced hot rolling mills that allow us to produce hot rolled stainless steel coils with precise dimensions and consistent quality. We have strict quality control measures in place to monitor the mechanical properties, chemical composition, and surface condition of the coils. Our quality control team conducts regular inspections and tests to ensure that each coil meets international standards. We offer customization options for our hot rolled stainless steel coils. Customers can specify the size, thickness, width, and surface finish of the coils according to their specific requirements. We also provide additional processing services, such as slitting and cutting to length, to facilitate the customer's production process. Our sales team has extensive knowledge of the applications of hot rolled stainless steel coils. They can provide technical advice and support to customers, helping them select the most suitable coils for their projects. We also offer competitive pricing and flexible delivery options to meet the diverse requirements of our customers. As we continue to expand our market reach to Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, we are confident that our hot rolled stainless steel coils will be in high demand. We invite new and existing clients to collaborate with us, leveraging our high - quality products and professional services for successful projects in various industries.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy