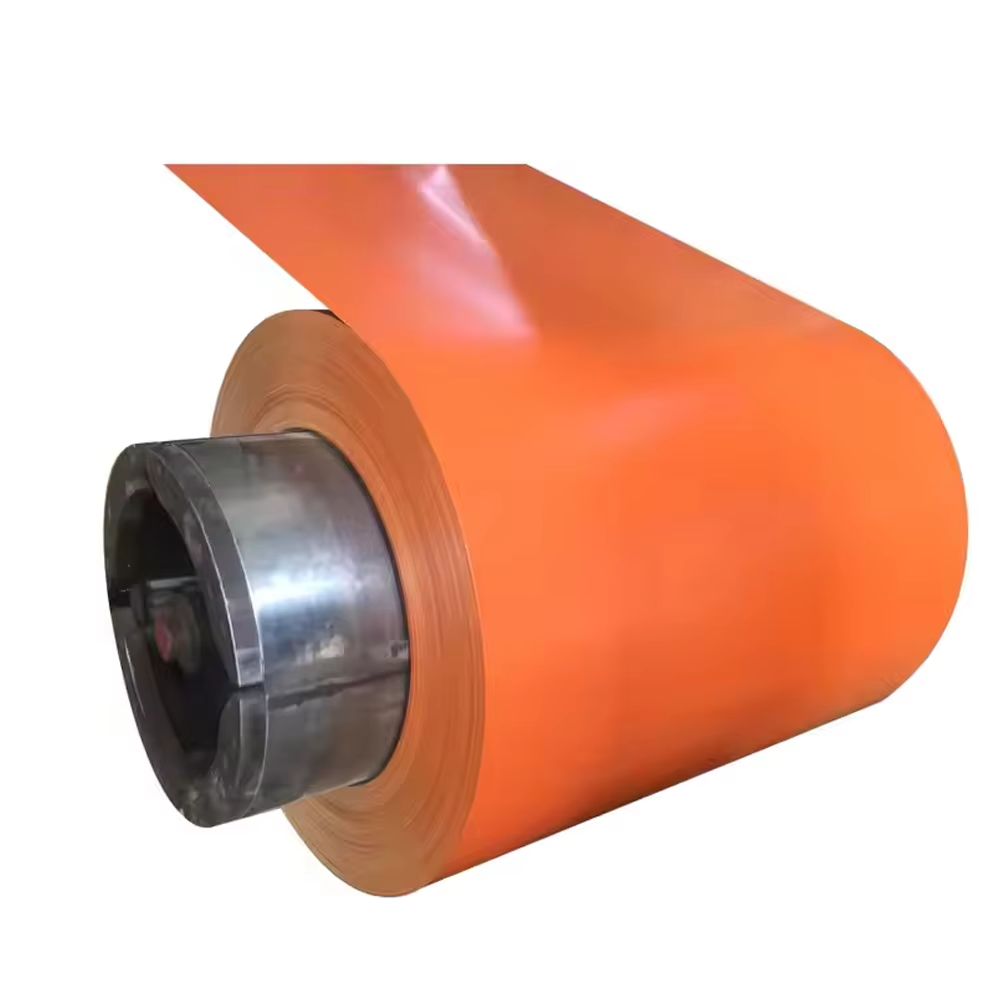

Zinc coated galvanized steel plate is a highly durable and corrosion - resistant steel product, and Liaocheng Mingxing Pipe Manufacturing Co., Ltd. has been a reliable supplier of high - quality zinc coated galvanized steel plates for the global market since its founding in 2016. The process of galvanization involves applying a layer of zinc to the surface of the steel plate. This zinc layer acts as a sacrificial anode, meaning it will corrode first instead of the steel, providing excellent protection against rust and corrosion. Galvanized steel plates are widely used in industries where the steel is exposed to harsh environmental conditions, such as construction, automotive, and outdoor equipment manufacturing. At Mingxing Pipe, we use advanced galvanization techniques to ensure a uniform and thick zinc coating on our steel plates. There are two main methods of galvanization: hot - dip galvanizing and electro - galvanizing. Hot - dip galvanizing is the most common method, where the steel plate is immersed in a bath of molten zinc. This results in a thick and durable zinc - iron alloy layer on the surface of the plate, providing long - lasting corrosion protection. Electro - galvanizing, on the other hand, uses an electric current to deposit a layer of zinc onto the steel plate, resulting in a thinner but more uniform coating. Our zinc coated galvanized steel plates are available in a variety of sizes, thicknesses, and zinc coating masses to meet the diverse needs of our customers. They can be produced in standard sizes or custom - cut according to the customer's specifications. The zinc coating mass can be adjusted based on the level of corrosion protection required for the specific application. In the construction industry, zinc coated galvanized steel plates are used for roofing, wall cladding, structural supports, and fencing. Their corrosion resistance ensures the longevity of the building structures, even in areas with high humidity or exposure to corrosive substances. In the automotive industry, these plates are used for the manufacture of vehicle bodies, chassis parts, and other components, where their durability and corrosion resistance are essential. We have strict quality control measures in place to ensure the quality of our zinc coated galvanized steel plates. Our quality control team conducts regular inspections and tests to check the thickness of the zinc coating, the adhesion of the coating to the steel, and the overall surface quality of the plates. We also perform corrosion resistance tests to verify the performance of the galvanized coating. Our sales team has extensive knowledge of the applications of zinc coated galvanized steel plates. They can provide technical advice and support to customers, helping them select the most suitable plates for their projects. We also offer competitive pricing and flexible delivery options to meet the diverse requirements of our customers. As we continue to expand our market presence in Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, we are confident that our zinc coated galvanized steel plates will be in high demand. We invite new and existing clients to collaborate with us, leveraging our high - quality products and professional services for successful projects in various industries.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy