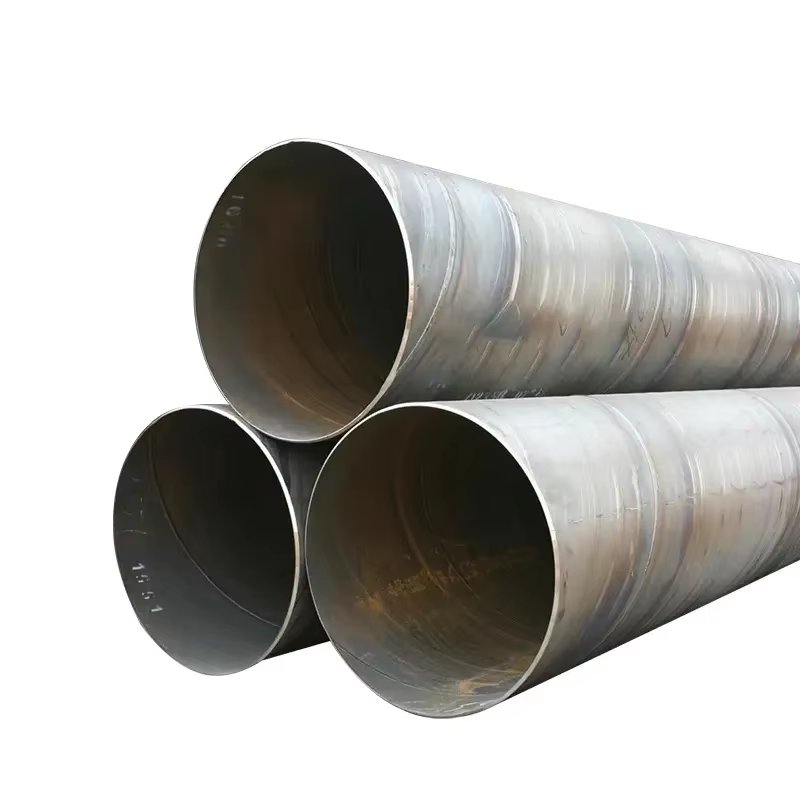

Rohre aus geschweisstem Stahl mit Hohlprofil sind ein wesentlicher Bestandteil des Produktspektrums, das von Liaocheng Mingxing Pipe Manufacturing Co., Ltd. angeboten wird. Seit unserer Gründung im Jahr 2016 haben wir uns der Produktion hochwertiger Stahlprodukte für den weltweiten Markt verschrieben, und auch bei Rohren mit Hohlprofil aus geschweisstem Stahl machen wir keine Ausnahme. Diese Rohre zeichnen sich durch ihr hohles Querschnittsprofil aus, was ihnen einzigartige Vorteile in Bezug auf Gewicht und Stärke verleiht. Im Baugewerbe werden geschweisste Stahlrohre mit Hohlprofil weitgehend zu strukturellen Zwecken eingesetzt. Ihre leichte Bauweise macht sie einfacher handhabbar und transportabel, wodurch Baukosten und -zeit reduziert werden. Gleichzeitig sorgt ihre hohe Stärke dafür, dass sie schwere Lasten tragen können, was sie für Rahmenkonstruktionen, Brücken und andere Großstrukturen geeignet macht. Die geschweisste Konstruktion dieser Rohre ermöglicht ein hohes Maß an Anpassungsfähigkeit. Wir können Rohre mit unterschiedlichen Formen wie quadratisch, rechteckig oder rund herstellen, um die spezifischen Designanforderungen verschiedener Projekte zu erfüllen. Diese Flexibilität im Design wird von Architekten und Ingenieuren sehr geschätzt, die nach innovativen Lösungen für ihre Bauprojekte suchen. Unsere Fabrik ist mit modernster Produktionsausrüstung ausgestattet, die es uns ermöglicht, geschweisste Stahlrohre mit Hohlprofil präzise und effizient herzustellen. Wir verwenden fortschrittliche Schweißtechniken, um die Integrität und Stärke der Verbindungen sicherzustellen. Unser strenger Qualitätskontrollprozess umfasst visuelle Inspektionen, zerstörungsfreie Prüfungen und mechanische Eigenschaftstests, um sicherzustellen, dass jedes Rohr den höchsten Standards entspricht. Neben dem Bauwesen finden geschweisste Stahlrohre mit Hohlprofil auch Anwendung in der Fertigung von Maschinen und Anlagen. Ihr hohles Profil kann genutzt werden, um elektrische Leitungen, hydraulische Systeme oder andere Komponenten unterzubringen, was eine ordentliche und übersichtliche Lösung bietet. Wir arbeiten eng mit Maschinenherstellern zusammen, um deren spezifische Bedürfnisse zu verstehen und Rohre anzubieten, die auf ihre Anforderungen zugeschnitten sind. Unser Verkaufsteam hat ein umfangreiches Wissen über die Anwendungen von geschweissten Stahlrohren mit Hohlprofil. Sie können technischen Support und Beratung bieten, um Kunden bei der Auswahl des richtigen Rohrtyps für ihre Projekte zu helfen. Egal ob es sich um ein kleines lokales Projekt oder ein großes internationales Unternehmen handelt, wir sind bestrebt, hochwertige Produkte und exzellente Dienstleistungen anzubieten. Wir bemühen uns stets, die Qualität und Leistungsfähigkeit unserer geschweissten Stahlrohre mit Hohlprofil zu verbessern. Unser Forschungs- und Entwicklungs-Team konzentriert sich darauf, neue Materialien und Produktionsverfahren zu entwickeln, die die Eigenschaften der Rohre, wie Korrosionsbeständigkeit und Brandschutz, verbessern können. Mit unseren modernen Produktionslinien, strenger Qualitätskontrolle und innovativem Ansatz sind wir zuversichtlich, dass unsere geschweissten Stahlrohre mit Hohlprofil weiterhin in hohem Maße nachgefragt werden werden auf Märkten weltweit, einschließlich Südostasien, dem Nahen Osten, Südamerika, Osteuropa, Afrika und Australien. Wir laden neue und bestehende Kunden ein, sich mit uns für langfristigen Erfolg zu partnerschaftlich zusammenzuschließen.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Datenschutzrichtlinie