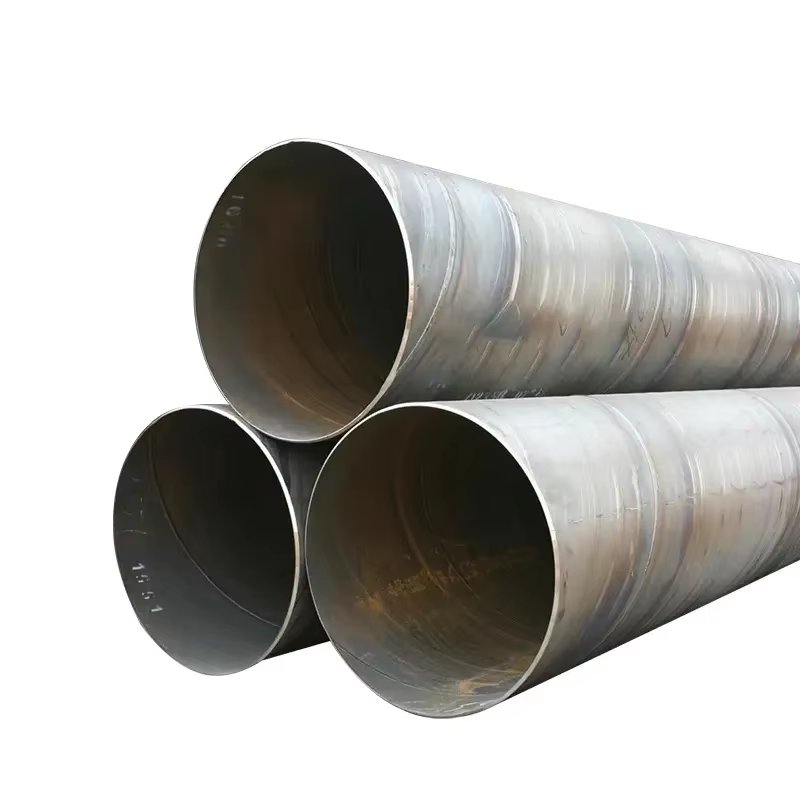

Les tubes soudés en acier au carbone sont un composant fondamental dans de nombreuses industries, et Liaocheng Mingxing Pipe Manufacturing Co., Ltd. est un acteur clé dans la production de tubes soudés en acier au carbone de haute qualité pour le marché mondial depuis sa création en 2016. L'acier au carbone, connu pour sa grande résistance, sa durabilité et son efficacité coûteuse, est le matériau principal utilisé dans la fabrication de ces tubes soudés. La construction soudée de ces tubes offre plusieurs avantages. Elle permet la production de tubes en longueurs plus grandes par rapport aux tubes sans soudure, réduisant ainsi le nombre d'assemblages nécessaires dans un système de pipeline. Cela minimise à son tour le risque de fuites et augmente l'efficacité globale du système. Chez Mingxing Pipe, nous utilisons des technologies de soudage avancées pour garantir l'intégrité et la force de nos tubes soudés en acier au carbone. Nos soudeurs qualifiés sont formés dans diverses méthodes de soudage, telles que le soudage sous arc enfoui (SAW), le soudage par résistance électrique (ERW) et la production de tubes soudés en spirale. Chaque méthode de soudage a ses propres avantages et est sélectionnée en fonction des spécifications particulières du tube, y compris sa taille, son épaisseur de paroi et son application prévue. Le processus de production des tubes soudés en acier au carbone commence par la sélection d'acier au carbone de haute qualité sous forme de plaques ou de bobines. Ces matériaux sont minutieusement inspectés pour les défauts de surface, la précision dimensionnelle et les propriétés mécaniques. Les plaques ou les bobines sont ensuite découpées aux longueurs requises et préparées pour le soudage. Pendant le processus de soudage, des mesures strictes de contrôle qualité sont mises en place pour surveiller les paramètres de soudage, tels que le courant, la tension et la vitesse de soudage, afin de garantir une qualité de soudure constante. Après le soudage, les tubes subissent une série de traitements post-soudage. Ceux-ci peuvent inclure un traitement thermique pour soulager les contraintes internes et améliorer les propriétés mécaniques des tubes, ainsi que des méthodes de contrôle non destructif (CND), telles que le contrôle par ultrasons, le contrôle radiographique et le contrôle par particules magnétiques, pour détecter tout défaut interne ou externe. Nos tubes soudés en acier au carbone sont disponibles dans une large gamme de tailles, de diamètres et d'épaisseurs de paroi pour répondre aux besoins variés de nos clients. Ils sont utilisés dans diverses industries, y compris le pétrole et le gaz pour le transport de pétrole brut, de gaz naturel et de produits raffinés ; les systèmes d'alimentation en eau et d'évacuation des eaux usées pour le transport d'eau et d'eaux usées ; et la construction pour les supports structurels et les échafaudages. Notre équipe de vente possède une connaissance approfondie des applications des tubes soudés en acier au carbone. Elle peut fournir des conseils techniques et un soutien aux clients, les aidant à sélectionner les tubes les plus adaptés pour leurs projets. Nous proposons également des options de personnalisation, telles que des finitions spéciales des extrémités, des revêtements et des doublures, pour améliorer la performance des tubes dans des environnements spécifiques. Alors que nous continuons à étendre notre présence sur les marchés de l'Asie du Sud-Est, du Moyen-Orient, de l'Amérique du Sud, de l'Europe de l'Est, de l'Afrique et de l'Australie, nous sommes confiants que nos tubes soudés en acier au carbone seront très demandés. Nous invitons les nouveaux et anciens clients à collaborer avec nous, en tirant parti de nos produits de haute qualité et de nos services professionnels pour des projets réussis dans diverses industries.

Droits d'auteur © 2025 par Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Politique de confidentialité