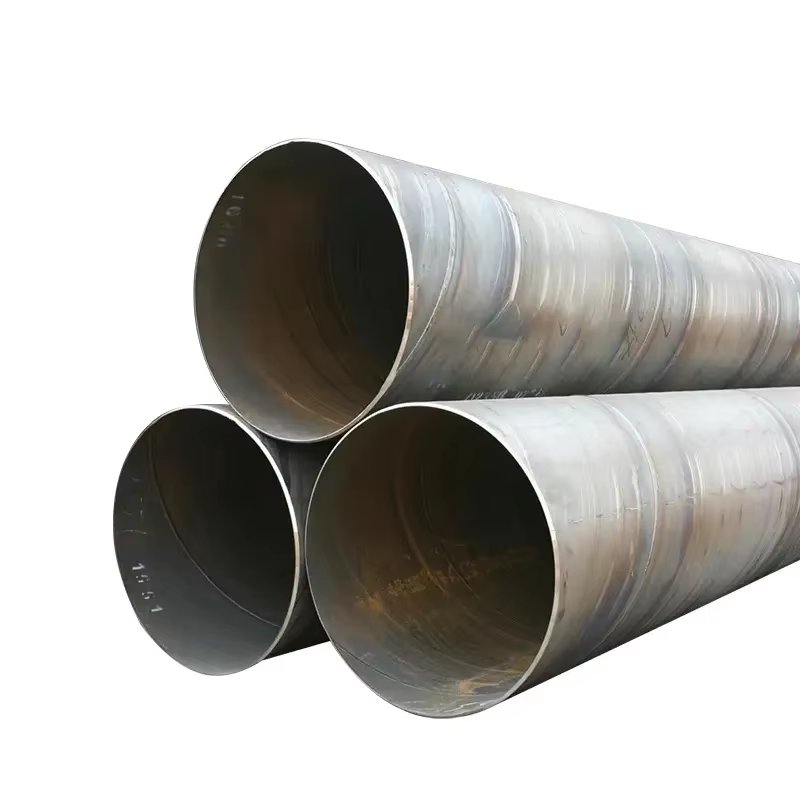

Píosaí acerach ollmhéinigh atá i gcuimhne ar phríomhphródúictí Liaocheng Mingxing Pipe Manufacturing Co., Ltd., cuideachta a bhfuil sí ina chleachtadóir cheannfortach sa ghluaiseacht soilse ó 2016. Ag Mingxing Pipe, tuigimid go bhfuil píosaí acera soilse ollmhéinigh riachtanach don leithscéal fada, ó chur chuige agus treorachta go dtí trasportail uisce agus gás. Tosaímid ar an gcuiditheacht ollmhéinigh nuair a roghnaimid ar chúramacha réad. Níl ach na n-orduithe soilse is fearr againn a chuireann méid leis an gcéim oibreacánach, mar éinntíocht ard, dúnlacht maith, agus cruthaitheacht. Tá ár dteangar féin ina chomhlachtaí le gearradh agus línte pródais a bhfuil againn chun píosaí acera soilse a chruthú le dimensiúní annamh agus comhréire bríogadh soiléir. Aontarimid le himeachtaí feirmeacha a bhfuil siad foghlamaíte i ngearradh nua-aimseartha chun cinntiú ar fhorbairt agus éinntíocht na ngearradh. Tá athruithe rialacha idirbhliana againn ar fheabhsú cúram, a bhaineann le hiomparálaí agus tástálaí i gcás gach cás de chuid an phróiseas pródais, ó thástáil na n-orduithe réad go dtí tástáil an phríomhphróducte. Mar thoradh ar a gcuiditheacht fhisiceálach, tá píosaí acera soilse ollmhéinigh againn a bhfuil acu forbairt corrúcháin maith. Is féidir linn cóipithe éagsúla a chur i bhfeidhm, mar chóipithe galvanised, cóipithe epoxy nó cóipithe 3PE, chun a gcéim corrúcháin a fheabhsú agus a shaothar beo a leathnú. Déanann sé seo iad comhshuite don úsáid i ngnáththéarmaithe, mar pháistí chósta nó páistí le háitíocht ard. Tá píosaí acera soilse ollmhéinigh againn ar fáil i míranna éagsúla, diámtraí agus tiolaithe balltuíche chun na ndíochaímí éagsúla ár gcustaiméirí a mhaireachtáil. Cén fhadhb a bhíonn sé do phroject beag áitiúil nó do sheasamh móór idirnáisiúnta, is féidir linn an cineál ceart de píosaí acera soilse a sholáthar chun an t-úsáid a chur i bhfeidhm. Tá ár gcomhghine den chomharthaíocht chun seirbhís custaiméireachta ollmhéinigh a sholáthar. Tá siad ag obair go níos giorra le custaiméirí chun a gcuid riachtanais speisialta a thuiscint agus tacaíocht téacsúil agus treoir a sholáthar tríd an gcéim cúinsíochta. Soláthraímid príosúnas cothrom le hoibríochta agus roghaí dorcha le cinntiú go bhfaighidh ár gcustaiméirí an ghearrthréaslú is fearr airgid amach as a gcuid airgead. Mar a fhágaimid ár gcáscaíocht fheabhsaithe i gcás Muintir an Ísle, an Mheán-Éire, Iarthar Meiriceá, An tEoraip Thoir, An Afraic agus An Astráil, tá súil againn go mbeidh ár dpíosaí acera soilse ollmhéinigh i gcás domhan-mhór. Roghnaímid cliant nua agus cinnte chun comhoibritheacht againn a dhéanamh, ag foshlánú ár n-eispéiris agus pródaití ollmhéinigh chun forbairt chumhachtach agus sainiúil a chur i bhfeidhm sa ghluaiseacht soilse domhanda.

Cóipcheart © 2025 ag Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Beartas Príobháideachta