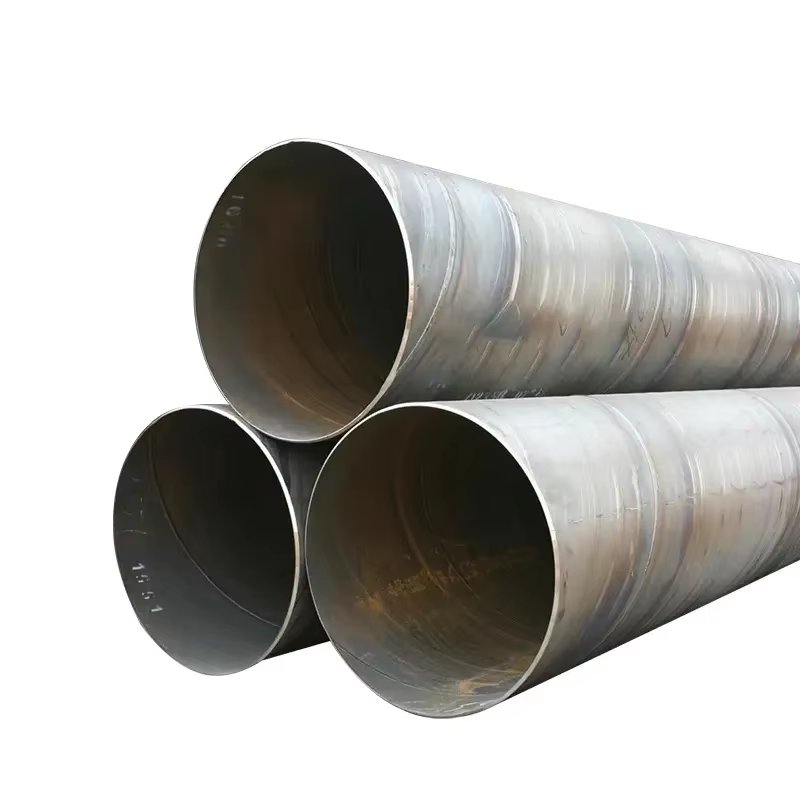

A szénbérgépírásos csövek alapvető komponensek számos iparágban, és a Liaocheng Mingxing Pipe Manufacturing Co., Ltd. 2016-os megalapításától fogva fontos szereplő a globális piac magas minőségű szénbérgépírásos csövek termelésében. A szénbér azért a fő anyag ezek a csövek gyártásához, mert kiváló erősségével, hosszú tartósággal és gazdasággal bír. A gépírásos szerkezetű csövek több előnnyel rendelkeznek. Lehetővé teszik a csövek hosszabb szakaszainak gyártását, amennyiben összehasonlítjuk őket a zárócsövekkel, így csökkentik a csatlakozási pontok számát egy csöves rendszerben. Ez pedig csökkenti a fertőzés kockázatát és növeli a rendszer teljesítményét. A Mingxing Pipe-ben haladó gépírásos technológiákat alkalmazunk, hogy biztosítsuk a szénbérgépírásos csöveink integritását és erősségét. Gyakorlatos gépíróink különféle gépírásos módszereket tanultak, például az áramfeszítetlen arkuszi gépírást (SAW), az elektromos ellenállású gépírást (ERW) és a spirálgépírásos csőtermelést. Minden gépírásos módszer saját előnyei vannak, és az adott cső követelményeitől függően, beleértve méretét, falvastagságát és célját, választjuk ki. A szénbérgépírásos csövek termelési folyamata a magas minőségű szénbér lapok vagy tárolók kiválasztásával kezdődik. Ezek anyagokat figyelmesen megvizsgáljuk felületi hibákra, dimenziós pontoságra és mechanikai tulajdonságokra. A lapok vagy tárolók aztán a szükséges hosszúságokra vágódnak és elkészülnek a gépírásra. A gépírás folyamatában szigorú minőségbiztosítási intézkedések vannak érvényben a gépírás paramétereinek figyelése érdekében, mint például az áramerősségre, a feszültségre és a gépírás sebességére, hogy konzisztens gépírás minőséget biztosítsunk. A gépírás után a csövek sorozatosan további utófeldolgozási eljárásokat menetelnek. Ezek közé tartozhat a hőkezelés, hogy enyhítsük a belső többlettömegeket és javítsuk a csövek mechanikai tulajdonságait, valamint a nem kiszabályozott vizsgálat (NDT) módszereit, mint például az ultrahangos vizsgálatot, a rádiográfiai vizsgálatot és a magnespartícula-vizsgálatot, hogy felmérjük bármilyen belső vagy külső hibát. Szénbérgépírásos csöveink széles körű méretekben, átmérőkben és falvastagságokban érhetők el, hogy feleljenek meg ügyfeleinink különféle igényeire. Azokat számos iparágban használják, beleértve az olaj- és gázipart, akrivel a nyersolaj, a természetes gáz és a rafinált termékek szállítása történik; a vízművek és a hulladékvíz-rendszerek, ahol víz és hulladékvíz továbbítása történik; valamint az építészetben, ahol strukturális támogató elemekként és gerincnek szolgálnak. A bolti csapatunk bőszen ismeri a szénbérgépírásos csövek alkalmazásait. Technikai tanácsot és támogatást tudnak nyújtani az ügyfeleknek, segítve nekik abban, hogy a legalkalmasabb csöveket válasszák projekteikhez. Rendelkezésünkre áll testreszabási lehetőségek is, mint speciális végrendezések, fedékek és belső berendezések, hogy növeljék a csövek teljesítményét bizonyos környezetekben. Ahogy tovább terjedünk az Ázsia déli részére, Közép-Keletre, Dél-Amerikára, Kelet-Európára, Afrikára és Ausztráliára, biztosak vagyunk abban, hogy szénbérgépírásos csöveink nagy keresletben lesznek. Meghívjuk az új és meglévő ügyfeleket, hogy partnerségi kapcsolatot alakítsanak ki velünk, és használják minőségi termékeinket és professzionális szolgáltatásainkat sikeres projektekhez számos iparágban.

Copyright © 2025 a Liaocheng Mingxing Pipe Manufacturing Co., Ltd.-től. Adatvédelmi irányelvek