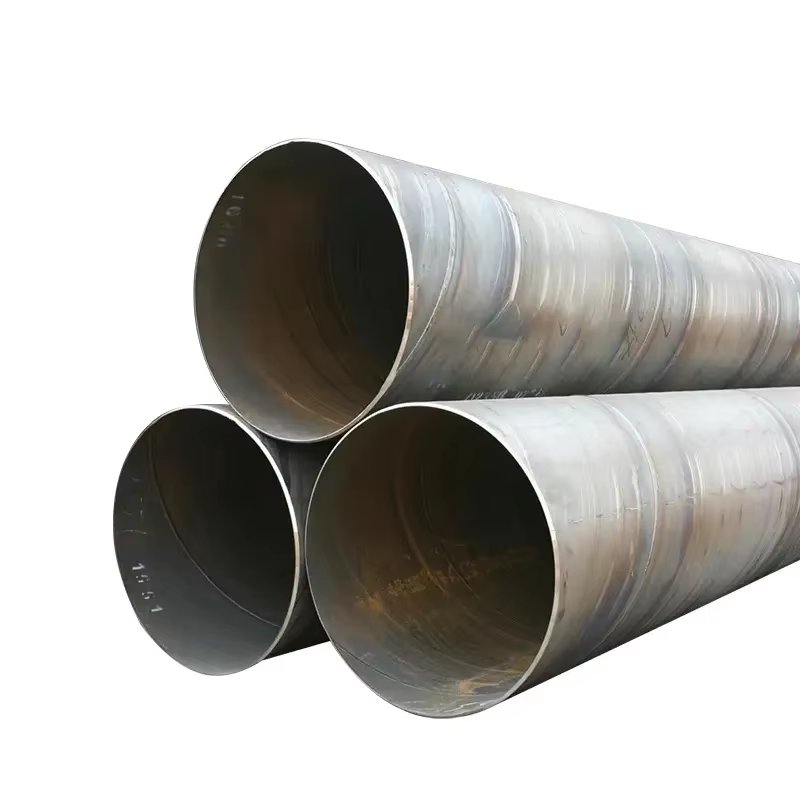

ท่อเหล็กเชื่อมสำหรับหม้อไอน้ำเป็นส่วนประกอบสำคัญในระบบหม้อไอน้ำ และบริษัท Liaocheng Mingxing Pipe Manufacturing Co., Ltd. ได้เป็นผู้ผลิตชั้นนำของท่อเหล็กเชื่อมคุณภาพสูงสำหรับตลาดโลกตั้งแต่ปี 2016 ในระบบหม้อไอน้ำ ท่อเหล่านี้มีหน้าที่ในการลำเลียงน้ำร้อน ไอน้ำ หรือของเหลวอื่น ๆ ภายใต้อุณหภูมิและความดันสูง ท่อเหล็กเชื่อมเป็นทางเลือกยอดนิยมสำหรับการใช้งานหม้อไอน้ำเนื่องจากสามารถผลิตได้ในความยาวที่มากกว่า ซึ่งลดจำนวนข้อต่อและจุดรั่วไหลในระบบลงได้ ที่ Mingxing Pipe เราใช้วัสดุเหล็กคาร์บอนคุณภาพสูงและเหล็กLOYเพื่อผลิตท่อเหล็กเชื่อมสำหรับหม้อไอน้ำ เหล็กเหล่านี้ถูกคัดสรรอย่างพิถีพิถันสำหรับความแข็งแรงที่อุณหภูมิสูง การต้านทานการกัดกร่อน และความสามารถในการนำความร้อน เราใช้เทคโนโลยีการเชื่อมขั้นสูง เช่น การเชื่อมอาร์กอนใต้น้ำและการเชื่อมด้วยแรงต้านไฟฟ้า เพื่อรับประกันความสมบูรณ์และความแข็งแรงของการเชื่อม กระบวนการผลิตท่อเหล็กเชื่อมสำหรับหม้อไอน้ำเกี่ยวข้องกับขั้นตอนสำคัญหลายขั้นตอน เราเริ่มจากการเตรียมแผ่นเหล็ก ซึ่งรวมถึงการตัด การงอ และการทำขอบเฉียง แผ่นเหล็กจะถูกเชื่อมเข้าด้วยกันเพื่อสร้างเป็นท่อ จากนั้นท่อจะผ่านกระบวนการบำบัดความร้อนเพื่อปรับปรุงคุณสมบัติทางกลและบรรเทาความเครียดภายใน วิธีการตรวจสอบแบบไม่ทำลาย เช่น การทดสอบด้วยคลื่นเสียงความถี่สูงและการทดสอบด้วยรังสี จะถูกใช้เพื่อตรวจสอบการเชื่อมสำหรับข้อบกพร่อง ท่อเหล็กเชื่อมสำหรับหม้อไอน้ำของเราสามารถหาได้ในหลากหลายขนาด เส้นผ่านศูนย์กลาง และความหนาของผนัง เพื่อตอบสนองความต้องการที่แตกต่างกันของระบบหม้อไอน้ำ ไม่ว่าจะเป็นหม้อไอน้ำอุตสาหกรรมขนาดเล็กหรือหม้อไอน้ำโรงไฟฟ้าขนาดใหญ่ เราสามารถให้ประเภทของท่อที่เหมาะสมกับการใช้งาน นอกจากประสิทธิภาพที่อุณหภูมิสูงแล้ว ท่อเหล็กเชื่อมสำหรับหม้อไอน้ำของเรายังมีการต้านทานการกัดกร่อนที่ดี เราสามารถเคลือบหรือทำการรักษาพิเศษให้กับท่อเพื่อเพิ่มการต้านทานการกัดกร่อน โดยเฉพาะอย่างยิ่งในสภาพแวดล้อมที่น้ำหม้อไอน้ำอาจมีสารปนเปื้อนที่สามารถก่อให้เกิดการกัดกร่อนได้ ทีมขายของเรา มีความรู้อย่างลึกซึ้งเกี่ยวกับอุตสาหกรรมหม้อไอน้ำและการใช้งานของท่อเหล็กเชื่อมสำหรับหม้อไอน้ำ พวกเขาสามารถให้คำแนะนำทางเทคนิคและการสนับสนุนแก่ลูกค้า ช่วยให้พวกเขาระบบท่อที่เหมาะสมที่สุดสำหรับระบบหม้อไอน้ำของพวกเขา นอกจากนี้เรายังให้คำแนะนำในการติดตั้งและการบริการหลังการขาย เพื่อให้มั่นใจว่าท่อได้รับการติดตั้งอย่างถูกต้องและทำงานได้อย่างมีประสิทธิภาพ เมื่อเราขยายตลาดไปยังเอเชียตะวันออกเฉียงใต้ ตะวันออกกลาง อเมริกาใต้ ยุโรปตะวันออก แอฟริกา และออสเตรเลีย เราเชื่อมั่นว่าท่อเหล็กเชื่อมสำหรับหม้อไอน้ำของเราจะได้รับความต้องการสูง เราขอเชิญลูกค้าใหม่และเดิมมาทำงานร่วมกับเรา โดยใช้ความเชี่ยวชาญและผลิตภัณฑ์คุณภาพสูงของเราเพื่อการดำเนินงานของระบบหม้อไอน้ำที่ประสบความสำเร็จ

ลิขสิทธิ์ © 2025 โดย Liaocheng Mingxing Pipe Manufacturing Co., Ltd. นโยบายความเป็นส่วนตัว