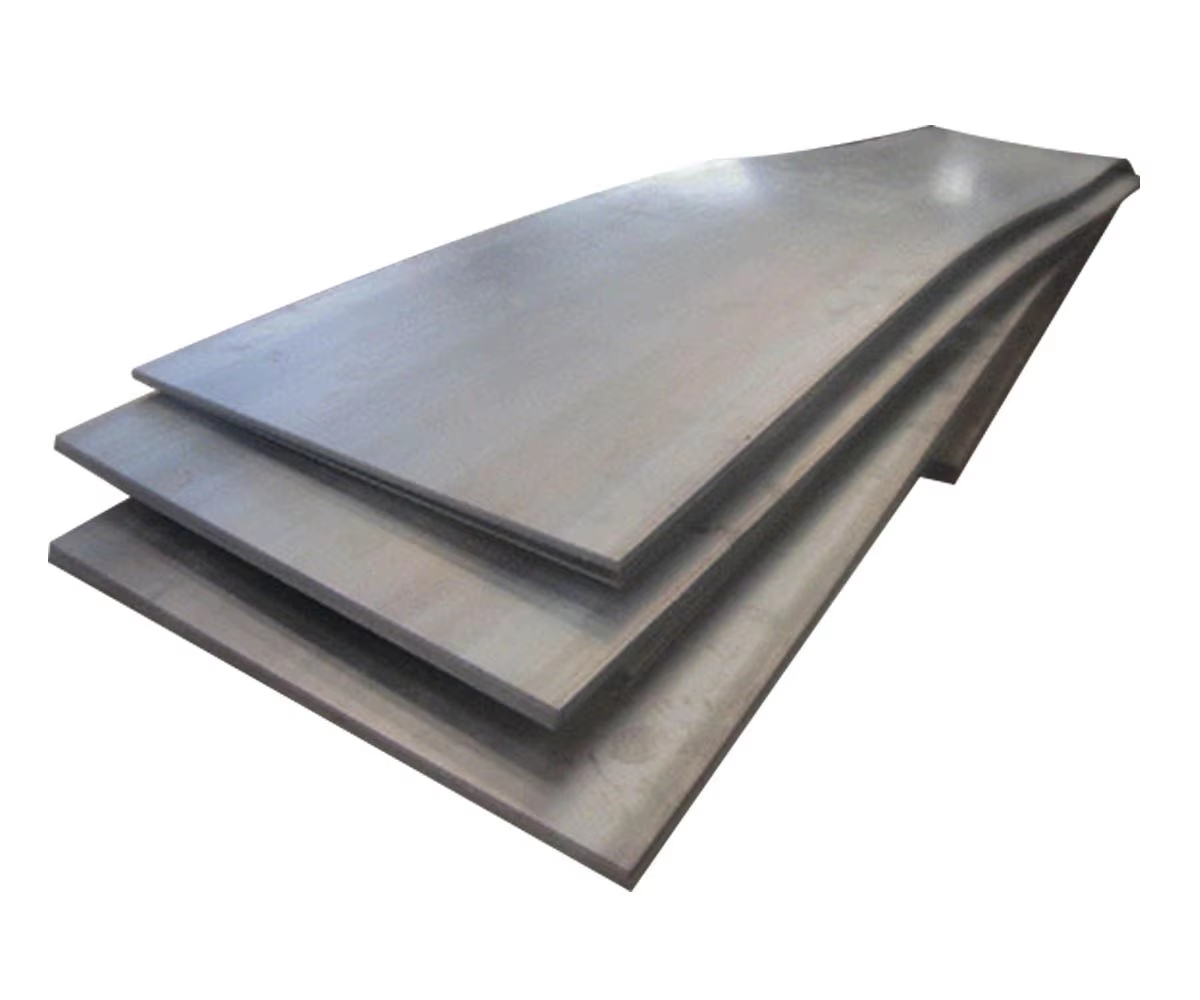

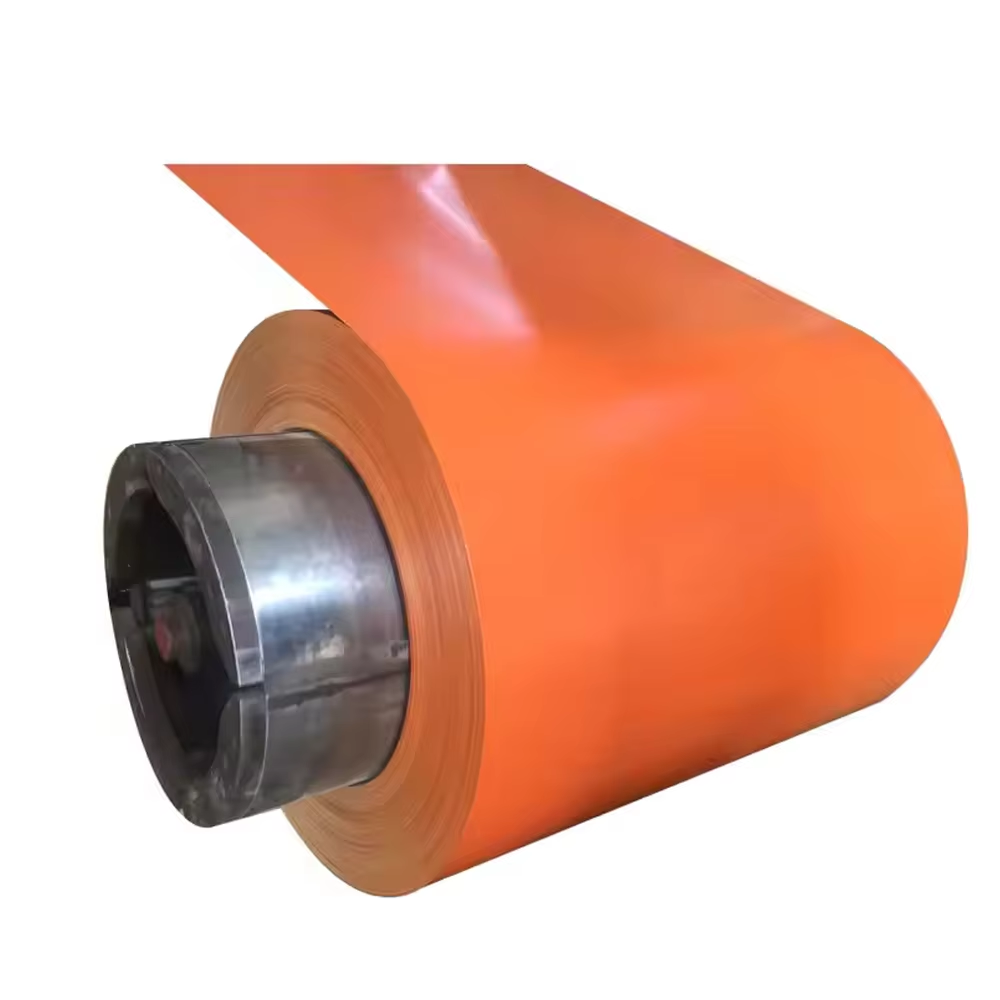

Carbon steel hot rolled coil is a fundamental product in the steel industry, and Liaocheng Mingxing Pipe Manufacturing Co., Ltd. has been at the forefront of producing high - quality carbon steel hot rolled coils since its founding in 2016. Carbon steel hot rolled coil is known for its excellent mechanical properties, such as high strength, good ductility, and toughness. These properties make it a versatile material that can be used in a wide range of applications. In the automotive industry, carbon steel hot rolled coil is used to manufacture various components, including chassis, body panels, and suspension parts. Its high strength allows for the production of lightweight yet durable parts, which can improve fuel efficiency and vehicle performance. In the construction industry, carbon steel hot rolled coil is used for the production of structural steel sections, such as I - beams, H - beams, and angles. These sections are used to build the frameworks of buildings, bridges, and other large - scale structures. The good ductility of the coil ensures that the steel can be easily formed into the desired shapes without cracking or breaking. Our factory is equipped with advanced hot rolling mills that can produce carbon steel hot rolled coils with precise dimensions and excellent surface quality. We use high - quality raw materials and strict production processes to ensure the consistency and reliability of our products. Our quality control team conducts regular inspections and tests to monitor the mechanical properties, chemical composition, and surface condition of the coils. In addition to its mechanical properties, carbon steel hot rolled coil also offers good weldability. This makes it easy to join the coils together or with other steel components, which is essential in many manufacturing and construction processes. We provide technical support to our customers to help them optimize their welding processes and ensure the quality of the welded joints. We are committed to environmental sustainability in the production of carbon steel hot rolled coil. Our factory has implemented various energy - saving and emission - reduction measures to minimize the environmental impact of our production activities. We also strive to use recycled materials in our production process, reducing the consumption of natural resources. As we expand our market reach to Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, we are confident that our carbon steel hot rolled coil will meet the high standards of our customers. We invite new and existing clients to collaborate with us, leveraging our high - quality products and professional services for mutual growth and success in the global steel market.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy