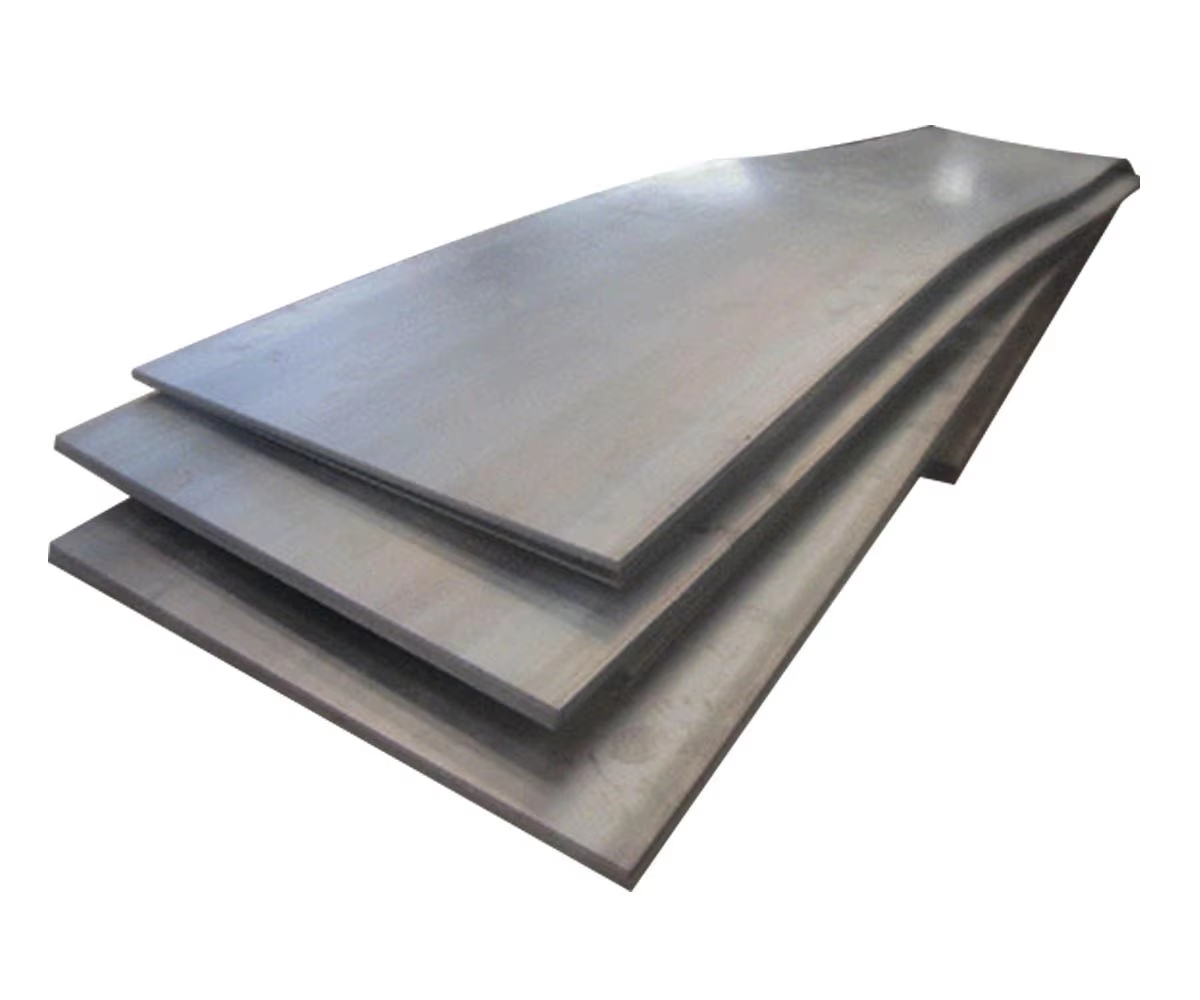

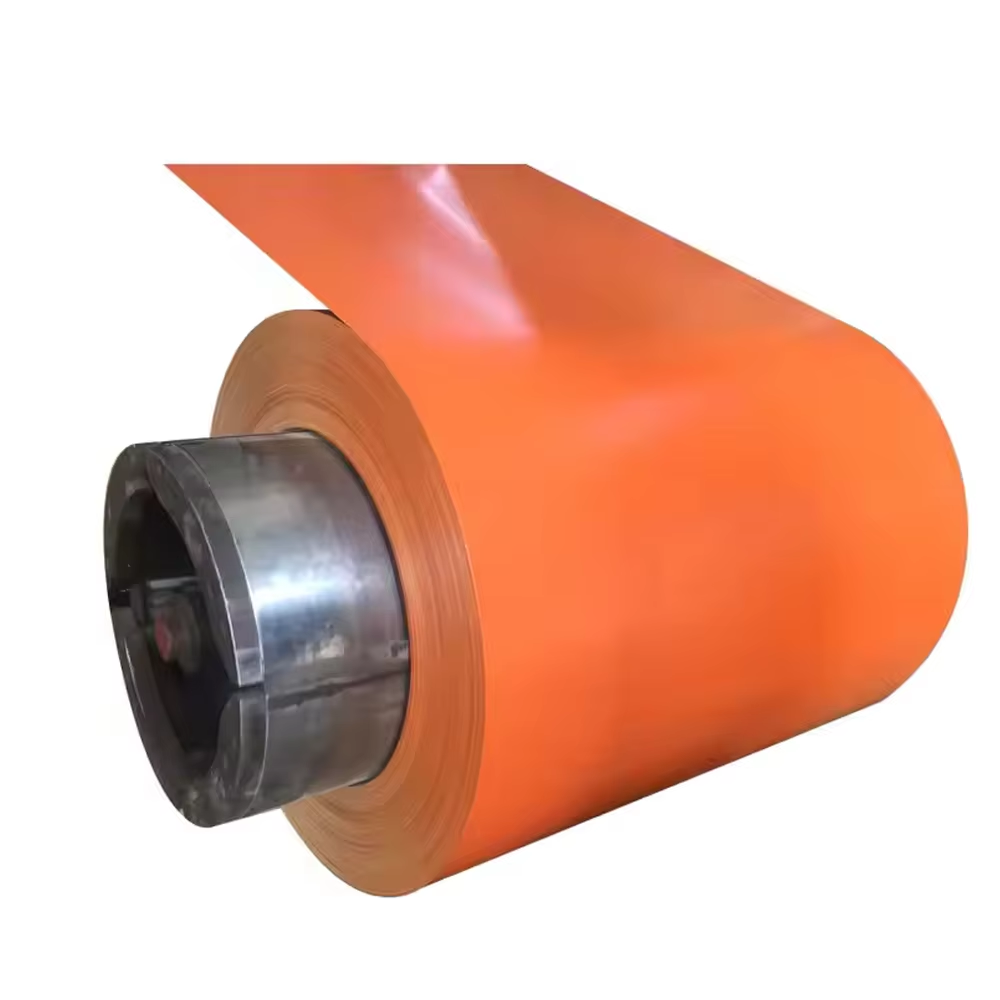

Machinery use hot rolled coil is a key product of Liaocheng Mingxing Pipe Manufacturing Co., Ltd., a company that has been dedicated to producing high - quality steel products for the global market since 2016. In the machinery manufacturing industry, hot rolled coil is used to produce various components, such as gears, shafts, and structural parts. The high strength and good machinability of hot rolled coil make it an ideal material for these applications. Our machinery use hot rolled coil is manufactured using advanced hot rolling processes that ensure precise dimensions and excellent surface quality. The production of machinery use hot rolled coil requires strict control of the chemical composition and mechanical properties of the steel. We use high - quality raw materials and advanced production technologies to produce coils that meet the specific requirements of the machinery manufacturing industry. Our quality control team conducts regular inspections and tests to monitor the hardness, tensile strength, and other mechanical properties of the coils. In addition to its mechanical properties, machinery use hot rolled coil also offers good weldability. This is important in the manufacturing of machinery, as many components need to be joined together through welding. We can provide technical support to our customers to help them optimize their welding processes and ensure the quality of the welded joints. Our machinery use hot rolled coil is available in a variety of grades and sizes to meet the different needs of our customers. Whether it's for a small - scale precision machinery or a large - scale industrial equipment, we can provide the right type of hot rolled coil to suit the application. Our sales team has extensive knowledge of the machinery manufacturing industry and can provide technical advice and support to customers. We work closely with machinery manufacturers to understand their specific requirements and provide solutions that can improve the performance and efficiency of their products. As we expand our market reach to Southeast Asia, the Middle East, South America, Eastern Europe, Africa, and Australia, we are confident that our machinery use hot rolled coil will be in high demand. We invite new and existing clients to collaborate with us, leveraging our high - quality products and professional services for mutual success in the machinery manufacturing industry.

Copyright © 2025 by Liaocheng Mingxing Pipe Manufacturing Co., Ltd. Privacy policy